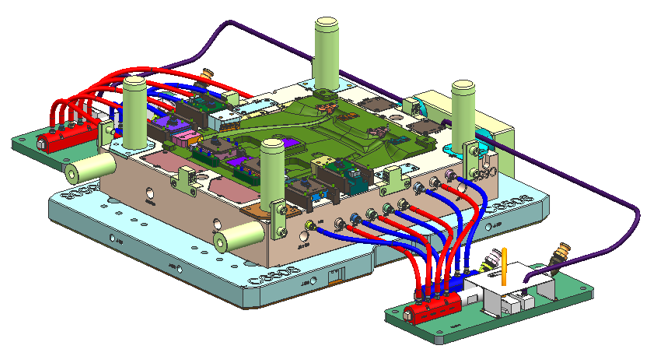

Nitrogen-assisted injection molding is a process that produces large plastic parts with complex designs and superb cosmetic surface finishes, which can save on material resources and avoid sink mark issues due to uneven wall thicknesses, etc.

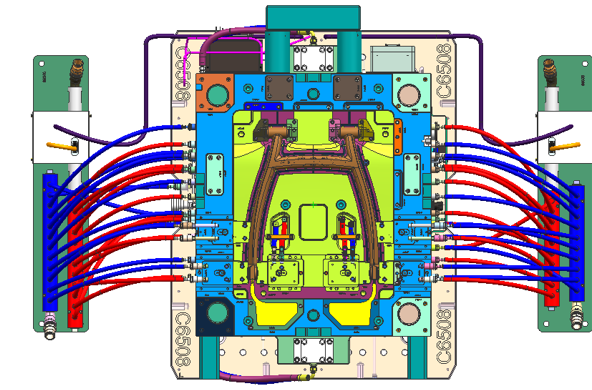

The Nitrogen-assisted injection molding process is a low-pressure, conventional injection molding process that forces a short shot of material to fill a mold by using pressurized nitrogen gas to displace the material in a pre-destined thick area while forming hollow sections in the part.

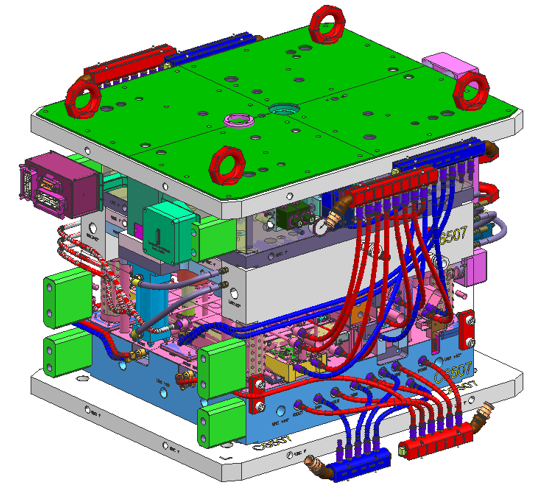

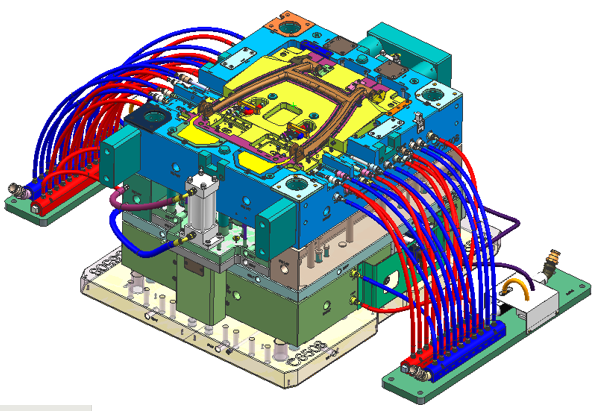

Before Nitrogen-assist injection mold design, we needed to run a Moldflow simulation to decide nitrogen gas pin location & size, overflow location & size, since a miss is as good as a mile!!!

National Hotline

National Hotline